So, I had multiple weld tanks connected to this system. It's good to have backup tanks for several reasons. Firstly, by having more than one tank, you can increase the pressure on the pressure switch without significantly reducing the capacity of the tanks. In this case, I have three 20-gallon tanks, each with a capacity of about five gallons. The pressure is set at 40-39 psi when it kicks on, and 54 psi when it kicks off. To adjust the maximum and minimum pressure levels, I reduced the height of the high-end screw on the pressure switch and increased the main screw. This way, the pump doesn't have to kick on frequently because there is enough working capacity with the 15 gallons of water available. Having a pressure in the 40s is beneficial for my reverse osmosis system. I purchased these tanks on Craigslist and had to clean them up and paint them. As long as they can hold air pressure and water pressure without being waterlogged, they are good to use. If the tank feels heavy and there is water sloshing around even when empty, it indicates a problem with the liner, and the tank is generally not suitable for use. In such cases, it's better to invest in a new tank, which can cost around $137. However, if you find a used tank in good condition and at a good price, it's worth considering. In this case, the tank is a flow tech with a plastic flange and a female one-inch connection. To connect it to the system, I used two one-inch male adapters glued together with a piece of one-inch PVC. To ensure a secure seal, I wrapped the connection with four layers of thick Teflon tape and added a layer of thread compound. Although it requires...

Award-winning PDF software

Shared well two pressure tanks Form: What You Should Know

Multiple pressure tanks on a shared well? Oct 30, 2025 — This system provides greater access to your pool and/or hot tub during the summer when the pool pump is not running. Single tank pressure control system · May 3, 2015, Multiple pressure tanks on a shared well? Jan 2, 2025 — I bought two new 20 gallon water pressure control tanks on a recent build. I thought I might add multiple well water pressure tanks to make my job a bit easier. But they come with a single tank and I need to add another tank to raise the pressure in the house. Plumbing a Shared Well Feb 22, 2025 — After having my home well checked in August 2025 my husband was surprised when the results came back that the test was negative! A simple test for water pressure control. “Water Pressure Control” Testing for a High Pressure Pump in Your Home July 4, 2025 — I got a positive test on the pressure control. Why did it show a normal test when we are supposed to have low pressure? Single tank pressure control system · Oct 22, 2025 Posted: I am looking to do some plumbing on my well as I have 4 bedrooms and a bathroom in the building (each a single house). I did the following: 1. I installed a single 20 gallon tanks on the outside of the home and a bladder tank (with water in the tube) inside the home. 2. On each side of the tank there are pressure controls. For the outside tank the pressure control valve is a 1-inch ball valve with a 2-second leak safety feature. The bladder tank has a 2-second leak. 3. After I got all the tank components in the house, I took the tank outside and connected a pressure washer and air line to that one tank. I installed a pressure washer on each side of the pressure washer and also used an air line on that tank. The tank was then attached and connected to a booster pump. It is still not quite stable though. The booster pump doesn't seem to have much power to pump the water out.

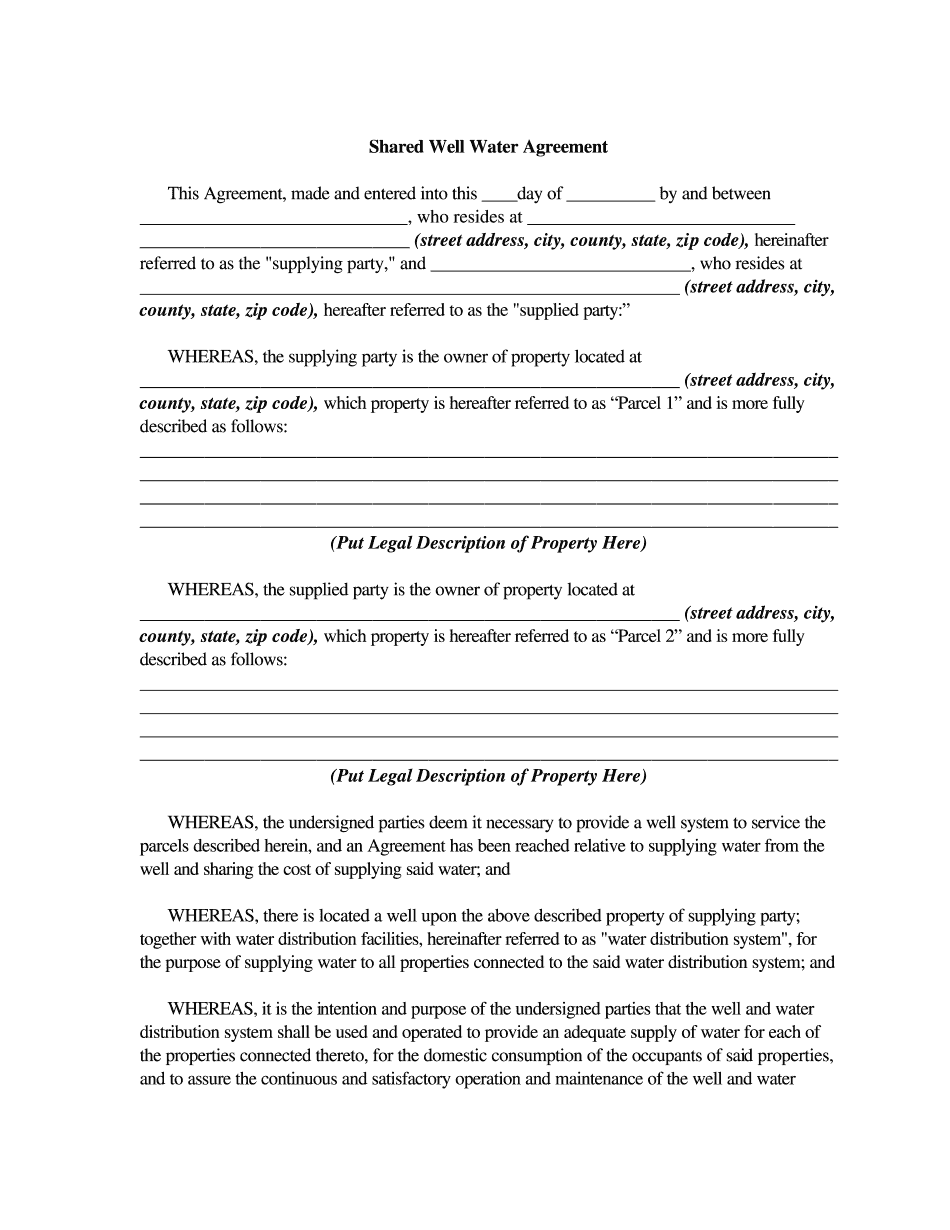

online solutions help you to manage your record administration along with raise the efficiency of the workflows. Stick to the fast guide to do Well Agreement form, steer clear of blunders along with furnish it in a timely manner:

How to complete any Well Agreement form online: - On the site with all the document, click on Begin immediately along with complete for the editor.

- Use your indications to submit established track record areas.

- Add your own info and speak to data.

- Make sure that you enter correct details and numbers throughout suitable areas.

- Very carefully confirm the content of the form as well as grammar along with punctuational.

- Navigate to Support area when you have questions or perhaps handle our assistance team.

- Place an electronic digital unique in your Well Agreement form by using Sign Device.

- After the form is fully gone, media Completed.

- Deliver the particular prepared document by way of electronic mail or facsimile, art print it out or perhaps reduce the gadget.

PDF editor permits you to help make changes to your Well Agreement form from the internet connected gadget, personalize it based on your requirements, indicator this in electronic format and also disperse differently.

Video instructions and help with filling out and completing Shared well two pressure tanks